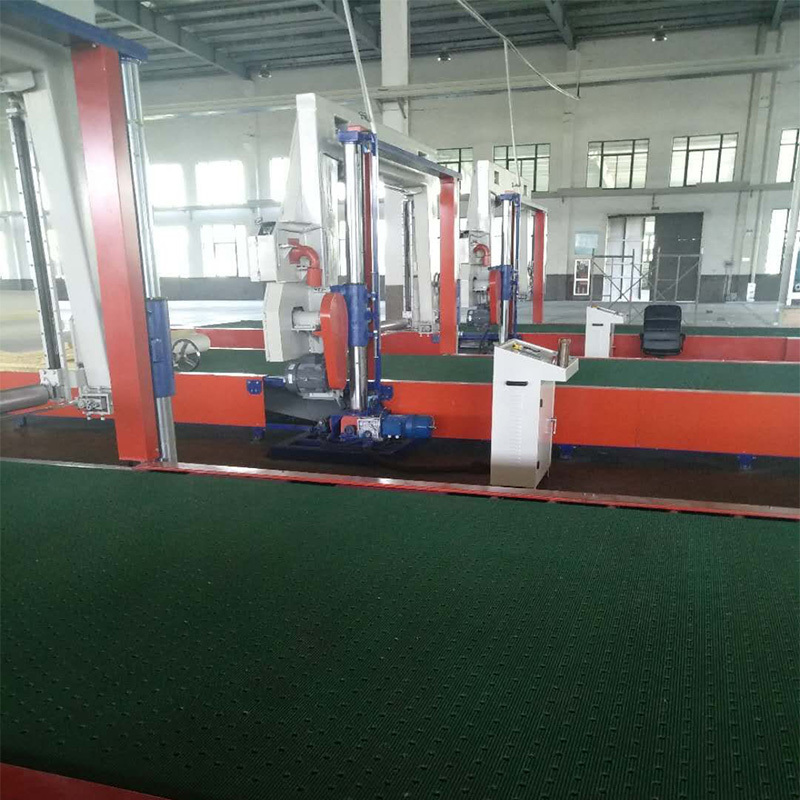

Thickness adjustment method for sponge track cutting machine

Release time:

2025-02-24

I. Principle

The sponge track cutting machine is a device commonly used for cutting materials such as sponges and foam plastics. Its thickness adjustment is achieved by adjusting the distance between the cutter and the cutting wheel. The greater the distance between the cutter and the cutting wheel, the thicker the cut material; the smaller the distance, the thinner the cut material.

II. Steps

1. In the servo system interface of the cutting machine, find the thickness adjustment option.

2. After entering the thickness adjustment option, select the adjustment method (manual or automatic) as needed.

3. In manual adjustment mode, make gradual fine adjustments as needed until the desired thickness is reached. In automatic adjustment mode, enter the required thickness value and press the "Confirm" button. The equipment will automatically adjust to the specified thickness.

4. After the adjustment is complete, perform a cutting test to confirm that the cutting effect meets the requirements.

III. Precautions

1. In order to avoid equipment performance degradation or failure due to excessive adjustment, it is recommended that users carefully read the product Description before performing thickness adjustment to understand the equipment's performance and limitations.

2. During the thickness adjustment process, the distance between the cutter and the cutting wheel of the cutting machine should be gradually fine-tuned. Avoid violent adjustment.

3. During the cutting test, it is necessary to confirm factors such as the blade position of the cutting machine and the stability of the material to ensure the accuracy and feasibility of the test results.

Previous Page

Previous Page

Latest News

Get a Free Consultancy

Approximately 110 meters west of the intersection of Haiping Line and Huanzhen East Road, Tongzhou District, Nantong City, Jiangsu Province, China.

Sweep and open the mobile phone

Feb 24,2025

Feb 24,2025