The working principle of a sponge trimming machine

Release time:

2025-02-24

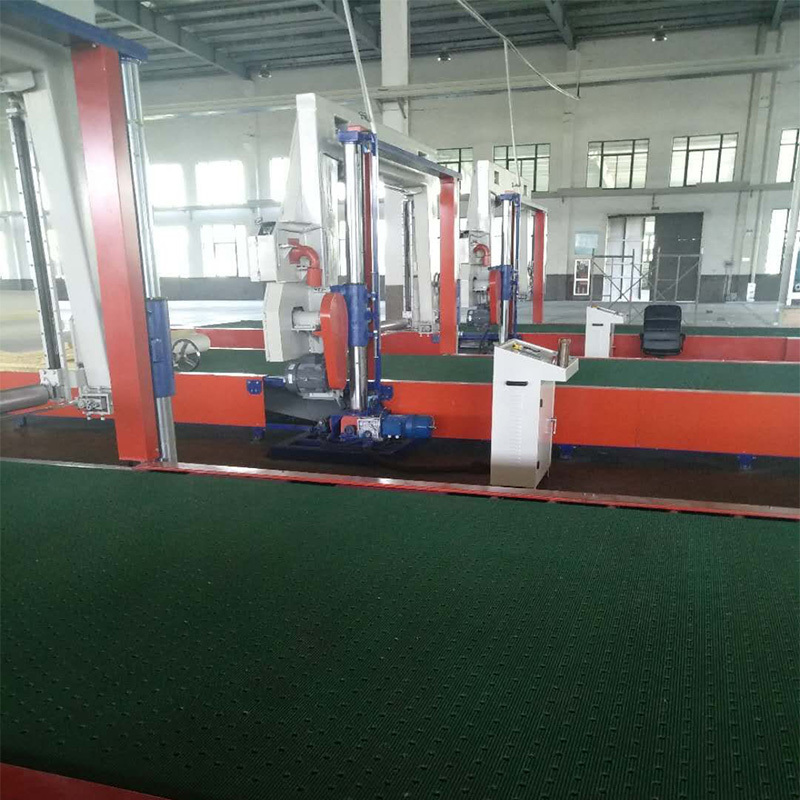

The working principle of a sponge trimming machine is mainly based on strong mechanical pressure. The main unit applies pressure to the sponge through the tool head, while the cutter cuts or carves the sponge surface. This process produces a large amount of wood chips and dust, and the machine's dust removal device can clean these impurities in time to keep the working environment clean.

Structural Features of a Sponge Trimming Machine

Sponge trimming machines typically include components such as a frame, conveyor wheels, guide rails, cutter frame support plate, left cutter frame, right cutter frame, gantry, upper support beam, crossbeam, motor, positioning frame, and positioning device. These components work together to reduce the frictional resistance of sponge movement, allowing the sponge to move steadily and flatly towards the trimming knife, ensuring the accuracy of trimming. In addition, the setting of the movable positioning frame can meet the accurate trimming of sponges of different widths.

Operating Procedures of a Sponge Trimming Machine

Power-on Preparation and Safety Check: Ensure stable power supply, check if all components are intact, start the computer control system and pneumatic system, and execute the calibration procedure.

Material Preparation and Loading: Select suitable sponge material and perform pre-treatment to ensure that the material surface is free of debris and wrinkles, and place it smoothly on the CNC machine platform.

Graphic Design and Parameter Setting: Call up the corresponding cutting graphics in the CNC system, and set appropriate cutting parameters according to the density, thickness, and cutting requirements of the sponge.

Tool Preparation and Sharpening: Select the appropriate tools for cutting operations, start the sharpening procedure, and ensure that the blades are sharp.

Positioning and Adjustment: Precisely position the sponge through the control panel or software interface, and adjust the position of the cutting knife.

Start Cutting and Monitoring: After confirming that all settings are correct, press the start button, closely monitor the machine's operating status, and adjust cutting parameters or stop the machine for inspection in time.

Cutting Completion and Subsequent Processing: Check the cutting quality, clean up the residual materials on the workbench, and check and replace worn cutting tools or saw blades.

Latest News

Get a Free Consultancy

Approximately 110 meters west of the intersection of Haiping Line and Huanzhen East Road, Tongzhou District, Nantong City, Jiangsu Province, China.

Sweep and open the mobile phone

Feb 24,2025

Feb 24,2025