What is the function of the frequency converter in a sponge foaming machine?

Release time:

2025-02-24

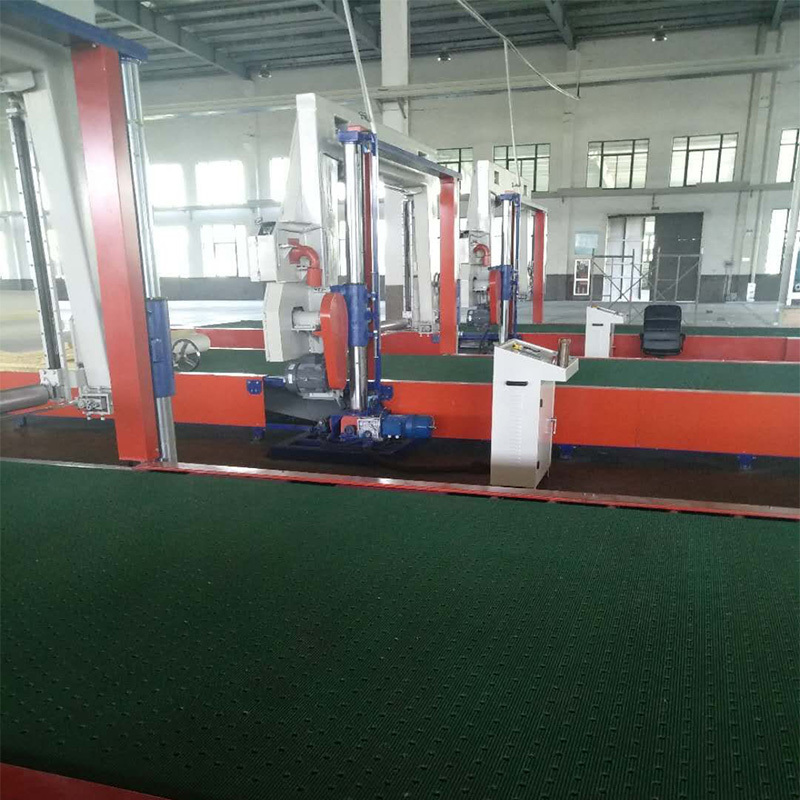

Sponge machinery sponge foaming machine, what is a foaming machine? As the name suggests, it is a machine that manufactures and produces foam. The quality of the sponge we produce is determined by factors such as the sponge foaming machine and the sponge foaming agent. So how do you use a sponge foaming machine to foam?

First, the sponge foaming agent should be adjusted according to the needs, and then the adjusted sponge foaming agent is poured into the sponge foaming machine. The sponge foaming agent contains beads, which will not foam before 80℃, but only continue to spread outwards. When the temperature exceeds 80℃, the beads in the sponge foaming agent begin to expand and soften, forming interconnected pores. The steam generated by the increase in temperature will also Enter these pores, and the pressure in the pores increases. As the temperature continues to rise and time passes, the above process continues until the gas pressure in the pores is large enough to break the pores, thus producing the common sponge. This is the working process of the sponge foaming machine. Remind the users of the sponge foaming machine that the sponge foaming agent must be adjusted well, otherwise, having a high-quality sponge foaming machine will not produce high-quality sponges, which is meaningless. Because consumers are becoming more and more picky, poor-quality sponges will eventually be eliminated. In order for enterprises to survive better, details must be paid attention to.

Secondly, the frequency converter is also an important equipment in the sponge foaming machine system. Its main function is to achieve raw material flow control, speed control and width adjustment of the side chain plate and bottom chain plate, sponge cutting, and sponge conveying.

The raw materials used by the factory to produce sponges generally do not exceed 12 types and are stored in 12 different control tanks. Since the raw materials used to produce each type of sponge are different, when the type of sponge is determined, the corresponding raw materials are also determined. At this time, the raw materials are injected into the raw material tank, and the corresponding mixing pump is opened for mixing, and then the corresponding frequency is set for the frequency converter.

The conveying of various raw materials is achieved by controlling the speed of the material pump through the frequency converter of the sponge foaming machine. The working principle is: the flow rate of raw material conveying is related to the speed of the material pump, and the speed of the material pump can be adjusted by changing the frequency of the frequency converter. According to the actual experience value of the project, the flow rate of the raw material conveying of the original sponge foaming machine material pump and the frequency of the frequency converter are corresponded, and the flow rate of the raw material can be determined by setting the frequency of the frequency converter once. This control scheme does not require cumbersome operations, which reduces the workload of workers and does not require high requirements for operators, making it easy to operate.

Previous Page

Latest News

Get a Free Consultancy

Approximately 110 meters west of the intersection of Haiping Line and Huanzhen East Road, Tongzhou District, Nantong City, Jiangsu Province, China.

Sweep and open the mobile phone

Feb 24,2025

Feb 24,2025