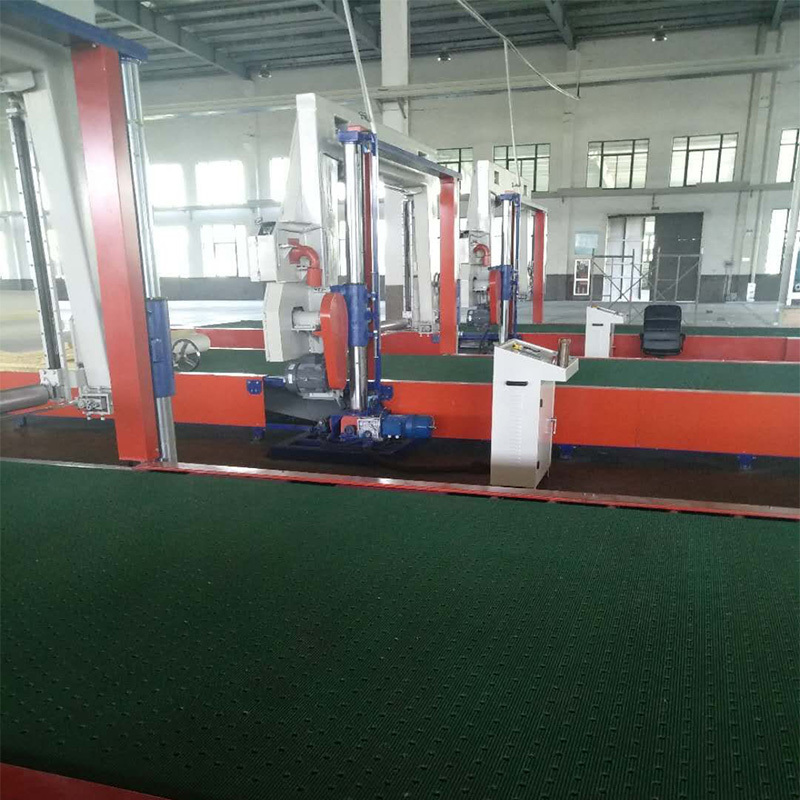

Cutting techniques and operation of sponge track rail cutting machines

Release time:

2025-02-24

Cutting techniques and operating procedures for a sponge rail trimming machine are as follows:

Machine preparation: Place the sponge rail trimming machine on a stable surface and check for any looseness or abnormalities. Ensure the stability of both the machine and the ground before turning on the machine.

Cutting preparation: Place the rail to be cut on the cutting table, check that the rail is positioned accurately, and adjust the table to a suitable operating position. Prepare the cutting blade and other accessories to be used.

Adjusting the cutting depth: Adjust the cutting depth according to the different shapes and sizes of the rail. The cutting depth should be adjusted gradually until the required depth is reached.

Start the machine: Press the start button to start the sponge rail trimming machine.

Controlling cutting speed and direction: During the cutting process, the cutting speed needs to be adjusted according to the different cutting materials and the degree of wear of the cutting blade. At the same time, control the cutting direction as needed. For higher accuracy, the speed and direction of movement of the blade can be manually controlled.

Complete the cutting: When the rail cutting is complete, turn off the machine and clean the cutting blade and accessories for next use.

Features and technical parameters of the sponge rail trimming machine:

Fully automatic digital control: According to the required cutting thickness and the density of the sponge, set the numerical value through the control box, and the machine automatically reciprocates on the rail.

Cutting angle of the blade guide: It can be adjusted from 0° to 5°, ensuring cutting flexibility and accuracy.

Latest News

Get a Free Consultancy

Approximately 110 meters west of the intersection of Haiping Line and Huanzhen East Road, Tongzhou District, Nantong City, Jiangsu Province, China.

Sweep and open the mobile phone

Feb 24,2025

Feb 24,2025